Poor electric quality can wreak havoc on your business. Improper wiring, unbalanced loads, and incorrect grounding are all examples of poor electric quality that can cause reliability issues with your service. Keystone offers power quality measurement to perform both the recording and the technical analysis. Utility power surges, lightning strikes, high impedance grounding, and faulty UPS capacitors are a small list of the vast array of services Keystone offers your business.

Examples of Poor Electric Power Quality

Many things can cause the wiring to be poor quality. Some of the common issues that can produce electric noise include:

- Improper wiring

- Unbalanced loads

- Incorrect grounding

- Data errors

- Memory loss

- Automatic resets

- Overheating of electrical systems

- Circuit board failure

- Equipment failure

- Software corruption

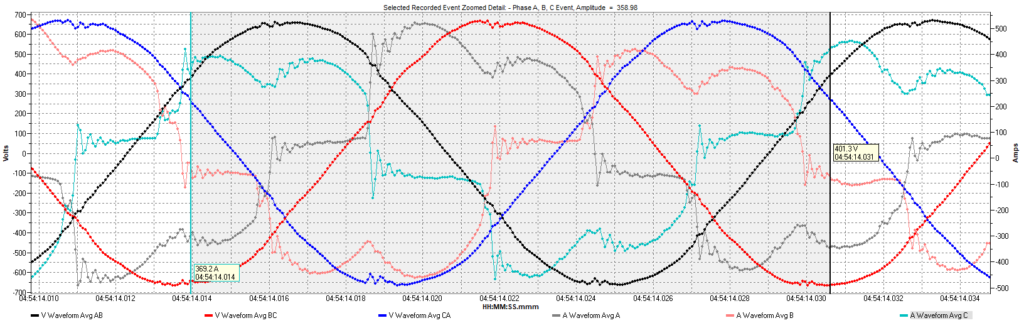

The source of these issues can vary. Issues such as power surges, voltage sag, transients, and interruptions can cause the voltage to fluctuate out of the healthy range.

Benefits of Keystone’s Power Quality Analysis and Reporting

There are many benefits when choosing Keystone’s power quality analysis:

Prevent Service Interruptions

Power quality analysis prevents service interruptions. Whether you experience a dip, a spike, a surge, or an outage, your service and machines stop. These outages can lead to decreases in productivity and efficiency- even if it’s for a moment.

Keystone offers reporting, meaning you can understand exactly what they did and why they did it.

Save Money

When your company loses productivity and efficiency, your company loses money. Outages can also lead to malfunctioning or even broken machinery. When this happens, you have no choice but to get your machinery fixed. This can be costly. Your company loses money because the machinery is not functioning as it should, and your company loses even more money for repairs. Earning less and spending more alienates you from your business goals.

Through finding and documenting the power issues, your business will get back in the black.

Allows for New Machinery

When you add new machinery to your company, the power is redistributed. If your service is not large enough, your company is much more likely to experience dips in both power and productivity. Before you decide whether to add new machinery, Keystone’s services can help you make an educated decision on exactly what type of new machinery is needed to maintain your level of productivity or even improve it.

Increased Safety

When machinery is overworked, it is guaranteed to overheat. This is a universal problem that anyone working with machinery deals with. When machines overheat, they run the risk of breaking down. Overheated machines run the risk of breaking down, which creates a very dangerous situation not only for your business’ machinery, but for your employees, as well. This can lead to employee injury or even death.

When your business is destroyed by a fire, you not only lose money to repairs but to being completely shut down. Your business also runs the risk of being sued for not providing a safe work environment.

Keystone’s power quality analysis and reporting can help your business prevent a catastrophe by catching potential issues early on.

Why Keystone

Keystone has a dedication to provide excellence, knowledge, and a personalized service. Donald Cleaver, Keystone’s founder and CEO, created the company in 2003 with a sole focus on the electronic environment.

Mr. Cleaver started in the industry as an HVAC apprentice in 1974. He later completed a mechanical engineering degree and now has 47 years of excellent electronic experience and knowledge. Eighteen years later, Keystone continues to accrue more and more customers, and it’s easy to see why!

Remember, Keystone gets IT.